Waspaloy - Chishandiso Chinogara Nguva refu Chekushandisa Pakupisa Kwakanyanya

| chiwanikwa | chinhu | C | Si | Mn | S | P | Mo | Cr | Al | Ti | Fe | Cu | B | Zr |

| Waspaloy | Minimum | 0.02 | 3.5 | 18.0 | 1.2 | 2.75 | 0.003 | 0.02 | ||||||

| Max | 0.10 | 0.75 | 1.0 | 0.03 | 0.03 | 5.0 | 21.0 | 1.6 | 3.25 | 2.0 | 0.5 | 0.01 | 0.12 | |

| zvimwe | Co:12.0~15.0,Ni:yakaenzana | |||||||||||||

| Mamiriro eAolly | Simba rekusimba RmMinimum Mpa | Simba rekupa RP 0.2Min Mpa | Kureba A5Minimum% | Kuderedza yeNzvimbo,miniti, % | Kuomarara kweBrinell HB |

| mhinduro + dzikamisa + kunaya kwemvura | 1100 | 760 | 15 | 18 | 310 |

| Kuwanda kwevanhug/cm3 | Nzvimbo Yokunyunguduka℃ |

| 8.19 | 1330~1360 |

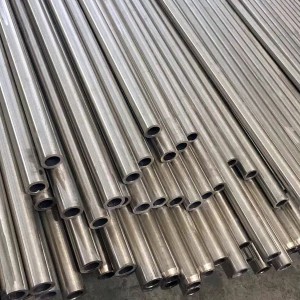

Tsvimbo, Bhawa, Waya uye Kugadzira Stock- ASTM B 637, ISO 9723, ISO 9724, ISO 9725, SAE AMS 5704, SAE AMS 5706,

Ndiro, Sheet uye Strip -SAE AMS 5544

Nyora meseji yako pano woitumira kwatiri