Nickel 200/Nickel201/ UNS N02200

| chiwanikwa | chinhu | Si | Mn | S | Ni | Fe | Cu |

| Nickel 200 | Minimum | ||||||

| Max | 0.35 | 0.35 | 0.01 | 99.0 | 0.4 | 0.25 | |

| Mashoko | Chinhu cheNickel 201 C i0.02, zvimwe zvinhu zvakafanana neNickel 200 | ||||||

| Mamiriro eAolly | Simba rekusimba Rm Min Mpa | Simba rekupa RP 0.2 Min Mpa | Kureba A 5 Min % |

| yakanyungudutswa | 380 | 105 | 40 |

| Kuwanda kwevanhug/cm3 | Nzvimbo Yokunyunguduka℃ |

| 8.89 | 1435~1446 |

Tsvimbo, Bhawa, Waya uye Kugadzira Stock- ASTM B 160/ ASME SB 160

Ndiro, Sheet uye Strip -ASTM B 162/ ASME SB 162,

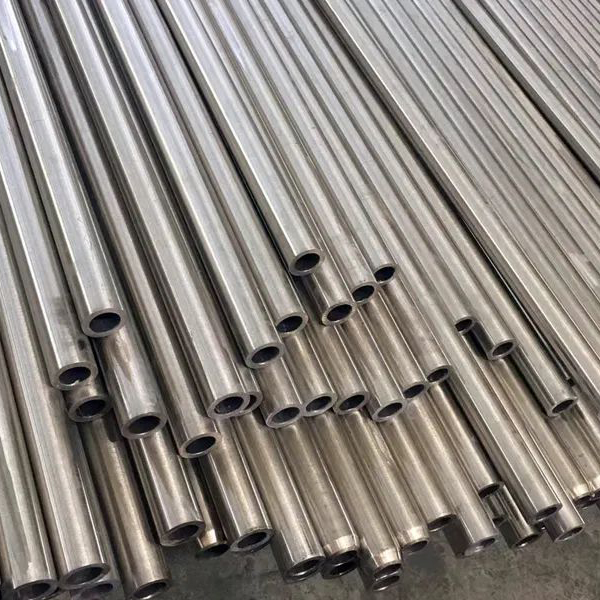

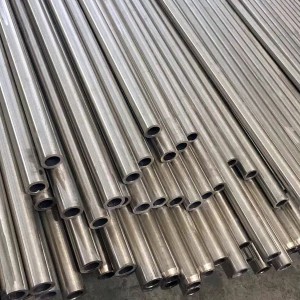

Pombi & Chubhu- ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/SB 775, B 829/ SB 829

Zvishandiso- ASTM B 366/ ASME SB 366

● Inodzivirira zvakanyanya makemikari akasiyana-siyana anoderedza kupisa

● Kudzivirira kwakanaka kwazvo ma alkali anouraya

● Kufambiswa kwemagetsi kwakanyanya

● Kudzivirira ngura zvakanaka mumvura yakacheneswa uye yechisikigo

● Kuramba mhinduro dzemunyu dzisina kwadzakarerekera uye dzine alkaline

● Kudzivirira zvakanyanya fluorine yakaoma

● Inoshandiswa zvakanyanya kubata soda inouraya utachiona

● Hunhu hwakanaka hwekupisa, hwemagetsi uye hwemagnetostrictive

● Inodzivisa hydrochloric nesulfuric acids pakupisa kuri pakati nepakati uye kuwanda kwayo