Kovar/UNS K94610

| chiwanikwa | chinhu | C | Si | Mn | S | P | Ni | Fe | Co | Mo |

| Kovar | Minimum |

|

|

|

|

| 28.5 |

| 16.8 |

|

| Max | 0.03 | 0.3 | 0.5 | 0.02 | 0.02 | 29.5 | kuenzanisa | 17.8 | 0.2 |

| Mamiriro eAolly | Avhareji yeCoefficient yemutsetse(10-6/°C) | ||||

| 20~200℃ | 20~300℃ | 20~400℃ | 20~500℃ | 20~600℃ | |

| yakanyungudutswa | 5.9 | 5.3 | 5.1 | 6.2 | 7.8 |

| Kuwanda kwevanhug/cm3 | Nzvimbo Yokunyunguduka℃ |

| 8.16 | 1450 |

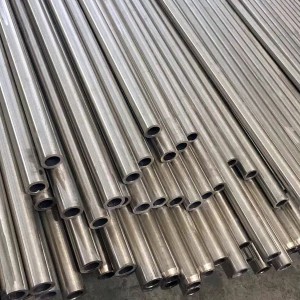

Tsvimbo, Bhawa, Waya uye Kugadzira Stock- ASTM F15

Ndiro, Sheet uye Strip -SAE AMS 7728

Nyora meseji yako pano woitumira kwatiri